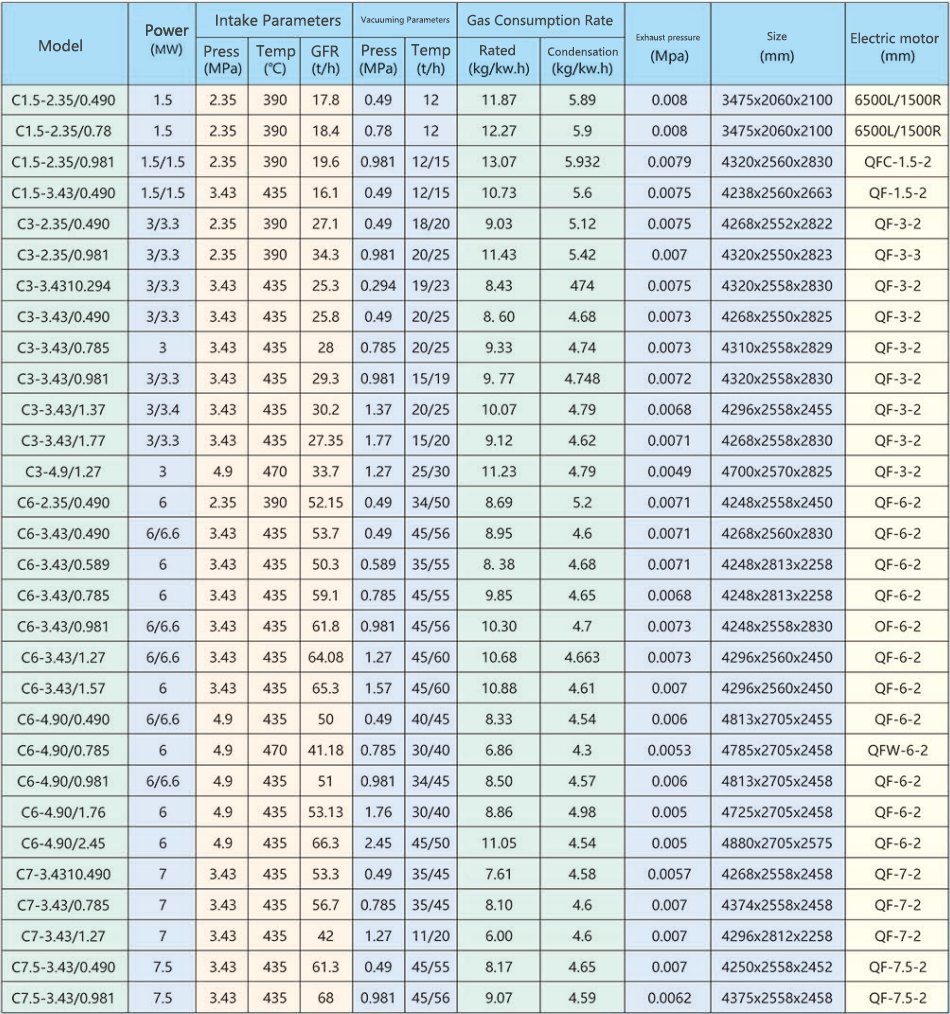

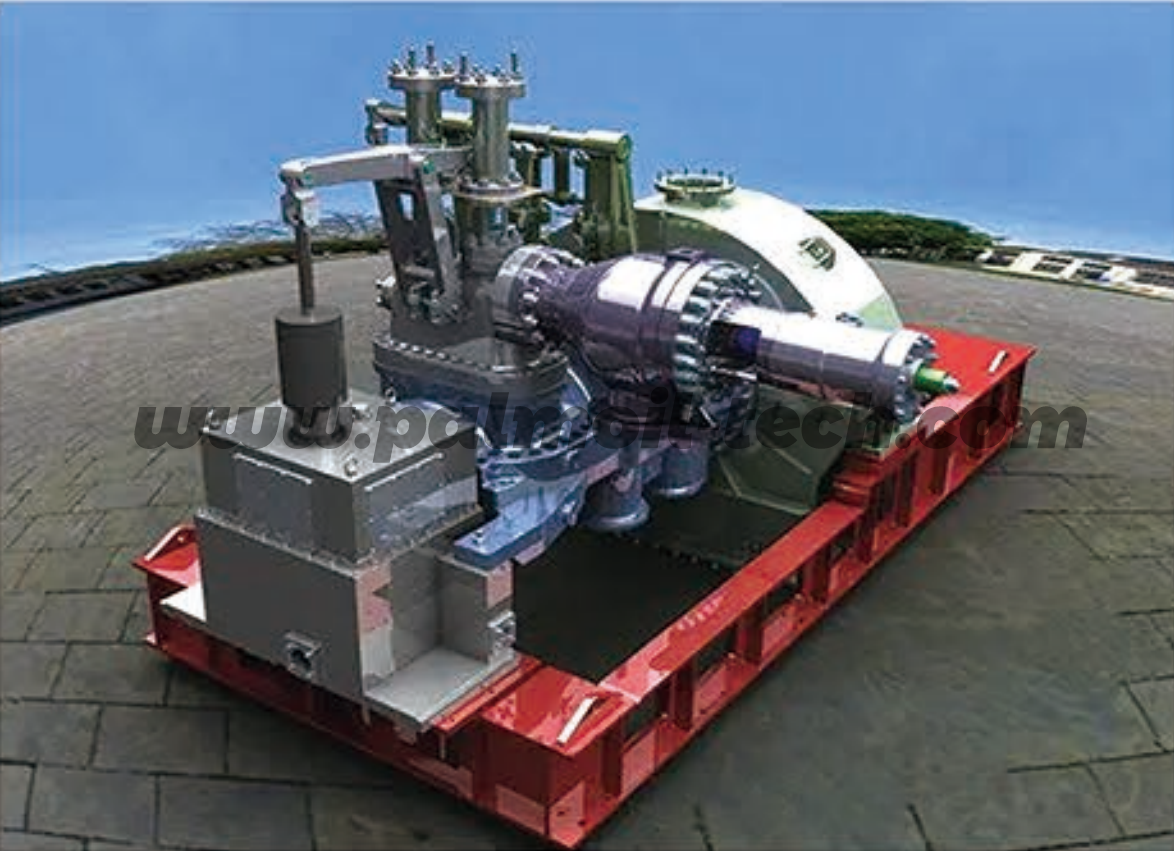

Extraction condensing steam turbine are single-cylinder, single-shaft impulse types with a single-stage regulating extraction. The unit's industrial extraction volume and electrical load can be automatically adjusted according to user requirements, and pure condensing operation is also permitted. All units in this series consist of rotor and stator components. The rotor adopts a sleeve-type structure, while the stator includes the cylinder, nozzles and baffles, labyrinth steam seals, bearings, and other parts. The high-medium cylinder lift plate-type regulating steam valve is mechanically linked to the hydraulic motor of the speed control system via levers. This series supports fully hydraulic speed control systems, imported governors, electro-hydraulic converters, automatic high-speed extraction devices, and various safety components and monitoring instruments. Single-extraction steam turbine. Composed of high-pressure and low-pressure sections, it functions as a combination of a back-pressure turbine and an extraction turbine. Fresh steam enters the high-pressure section to perform work. After expanding to a certain pressure, it splits into two streams: one is extracted to supply heat users, while the other enters the low-pressure section for further expansion and work before being discharged into the condenser.

Extraction condensing steam turbine are single-cylinder, single-shaft impulse types with a single-stage regulating extraction. The unit's industrial extraction volume and electrical load can be automatically adjusted according to user requirements, and pure condensing operation is also permitted. All units in this series consist of rotor and stator components. The rotor adopts a sleeve-type structure, while the stator includes the cylinder, nozzles and baffles, labyrinth steam seals, bearings, and other parts. The high-medium cylinder lift plate-type regulating steam valve is mechanically linked to the hydraulic motor of the speed control system via levers. This series supports fully hydraulic speed control systems, imported governors, electro-hydraulic converters, automatic high-speed extraction devices, and various safety components and monitoring instruments. Single-extraction steam turbine. Composed of high-pressure and low-pressure sections, it functions as a combination of a back-pressure turbine and an extraction turbine. Fresh steam enters the high-pressure section to perform work. After expanding to a certain pressure, it splits into two streams: one is extracted to supply heat users, while the other enters the low-pressure section for further expansion and work before being discharged into the condenser.

Steam Turbine Structural Features:

. Configuration: Quick-assembly multi-stage steam turbine

· Arrangement: Double-deck

· Mechanical Speed Control: Fully hydraulic regulation

· Electronic Speed Control: Electro-hydraulic converter governor, integrated control system comprising four major systems (governor, control, detection, protection)

· Overspeed Protection: Mechanical fly-hammer protection with electromagnetic valve electronic intelligent control

· Steam Seal Type: Stainless steel labyrinth steam seal, honeycomb contact steam seal

· Main Steam Valve: Integrated automatic main steam valve (combination valve with quick-closing regulation)

· Main shaft assembly: Restart stage rotor blades, interference fit between rotor and rotor blades

· Lubrication system: Oil lubrication (with integrated lubrication station)

· Thermal expansion compensation: Sliding thermal compensation for front bearing support

· Electrical configuration: Complete set of electrical control cabinets, protection cabinets, main control cabinets, with domestic generator (voltage 400-6300-10050V)

· Turbine Turning Method: Manual or Electric

The design extraction pressure is determined based on thermal user requirements and controlled by a pressure regulator to maintain stable extraction pressure. The power output of a single extraction steam turbine is the sum of power generated by the high- and low-pressure sections, determined by the steam inlet volume and the steam flow through the low-pressure section. Adjusting the steam inlet volume allows for different power outputs. Therefore, within a certain range, both thermal and electrical load requirements can be simultaneously met. When the heat extraction steam flow is zero, a single extraction steam turbine functions as an extraction condensing turbine. If all steam entering the high-pressure cylinder is extracted for heat users, it operates as a back-pressure turbine. However, in actual operation, a certain amount of steam must flow through the low-pressure section into the condenser to cool the low-pressure cylinder and dissipate heat generated by friction losses. The minimum required flow rate is approximately 10% of the low-pressure cylinder's design flow rate.