We are industry leaders in micro-turbine manufacturing, boasting extensive experience, low profit margins, and high quality. Our operations rely on consistent production volumes to sustain the company. We welcome more clients to partner with us, driving us to produce even more efficient turbines.

Performance Features:

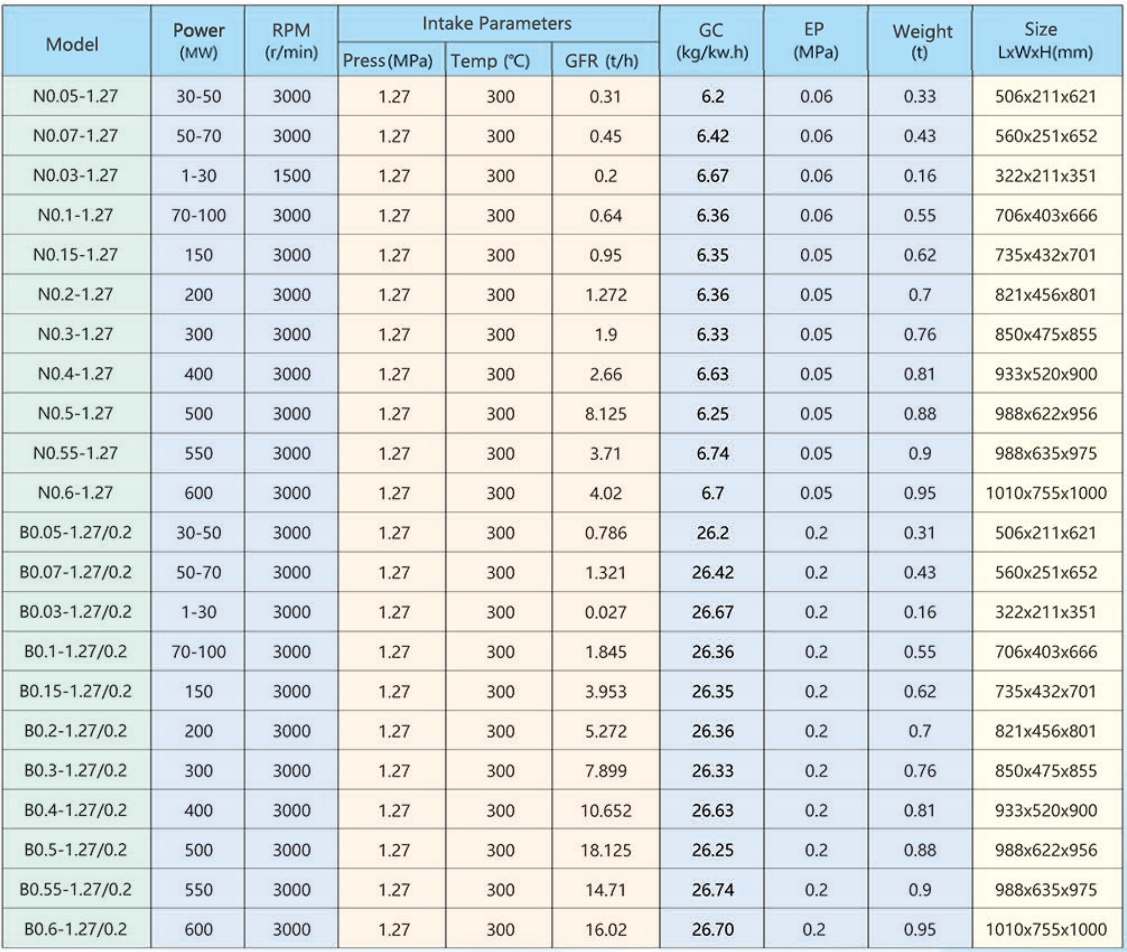

The M and H series turbines include back-pressure and condensing types. Impeller pitch circle diameters range from 380 to 500 mm, with main shaft speeds of 3000 and 5600 rpm. They utilize fresh steam or waste heat exhaust steam, saturated or superheated steam, with inlet steam pressure as low as 0.15 MPa. Power range: 1KW-650KW power generation turbine units. Primarily applied in ceramics, cement, power plants, chemical, chemical fiber, papermaking, sugar refining, steel, waste treatment, and energy utilization sectors such as corporate captive power stations, district cogeneration, municipal waste-to-energy plants, and gas-steam combined cycle power generation. The equipment offers lower operating costs and more significant economic benefits. Our company is committed to providing users with first-class products and premium services!

Unit Features:

Wide operating range: 0.15 MPa to 2.5 MPa working pressure.

Single-layer skid-mounted installation design tailored to power requirements and user specifications.

Also known as micro-turbines, these units feature simple installation—fully assembled within 5 days of delivery and commissioned within 2 days.

Control Method:

Simple structure, easy operation, high safety factor, equipped with a human-machine interface touchscreen control panel.

Steam source can be either superheated steam or saturated steam.

The turbine generator set adopts a direct-coupling configuration, ensuring high safety, long service life, and reduced susceptibility to damage.

Key Point:

Custom-designed turbines tailored to actual user parameters to accommodate diverse steam sources.