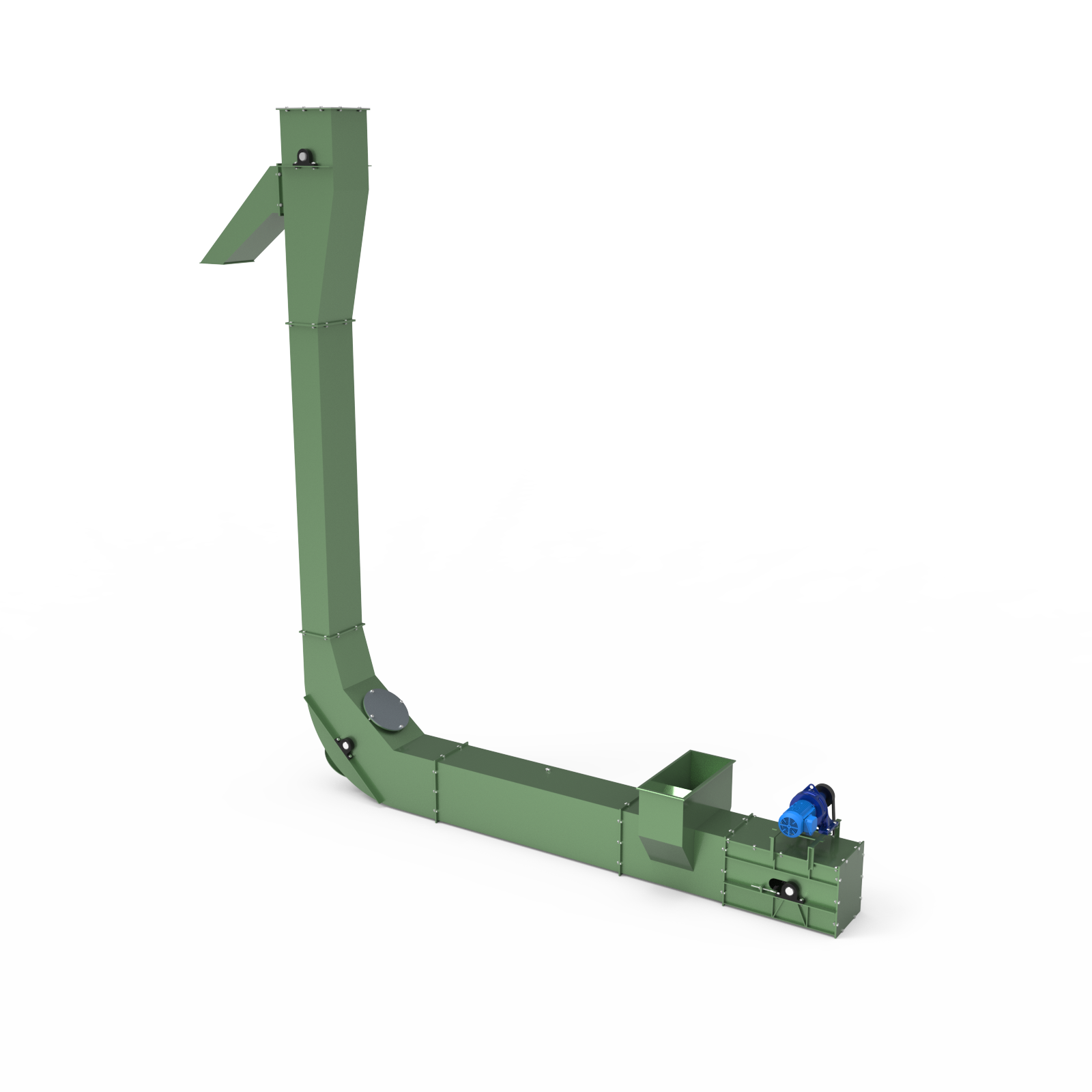

Product OverviewAn enhanced conveying solution for oil extraction processes, featuring integrateddrainage screen platesandcompression sectionsto pre-desolventize wet meal. This reduces steam consumption in desolventizer-toasters (DTDC), lowers residual oil/solvent in meal, and increases overall production capacity.Key FeaturesEnergy Efficiency:Pre-removes 15-20% solvent from wet mealCuts DTDC steam consumption by 25-30%Compact Design:Space-saving structure with multi-point loading/unloading30% lighter than conventional conveyorsBidirectional Operation:Simultaneous material transport in opposite directionsExplosion-Proof Safety:Low-speed operation (≤0.2 m/s) minimizes ignition risksIP65-rated enclosure for hazardous environmentsWorking PrincipleWet meal enters enclosed troughDrag chains move material through:Drainage screens: Gravity-based solvent removalCompression zone: Mechanical dewateringPre-dried meal discharges to DTDCRecovered solvent returns to extraction cycleApplicationsOilseed Processing: Transporting solvent-laden wet meal (soybean, rapeseed)Hazardous Material Handling: Dusty, toxic, or explosive powdersEnvironmental Protection: Fully enclosed design prevents VOC emissionsTechnical SpecificationsParameterRangeCapacity5-200 TPHTrough Width300-1000 mmChain Speed0.05-0.2 m/sPower3-30 kWMaterialSS304/316L carbon steelMaintenanceDaily: Inspect chain tension and screen cleanlinessWeekly: Lubricate bearings; check wear linersMonthly: Calibrate explosion relief valvesAnnually: Replace chain/sprocket assembliesConclusionThe Enclosed Drag Chain Conveyor delivers15% operational cost savingsthrough integrated solvent recovery and failsafe hazardous material handling. Engineered for maximum reliability in oil extraction plants, it supports sustainable production while meeting ATEX Zone 21 safety standards.

IntroductionLight steel prefabricated houses are innovative structures utilizing light steel studs as their primary load-bearing framework. These frames are manufactured from hot-dip galvanized steel strips through cold-forming processes, delivering exceptional strength and toughness. Unlike traditional construction methods, light steel houses relocate significant work to factories. Through standardized, industrialized production, high-precision components are prefabricated and transported to sites for rapid assembly, fundamentally transforming conventional building practices.FeaturesLightweight & ConvenientThe structural materials used are high-strength yet lightweight. This reduces transportation and hoisting costs while lowering foundation loads, thereby decreasing foundation expenses. With minimal foundation requirements, these structures are particularly suited for challenging terrains like mountains, riverbanks, sandy areas, and islands.Safety and DurabilityThe roof truss structure combined with interior and exterior wall panels forms a robust plate-rib system, significantly enhancing load-bearing capacity and providing superior earthquake and wind resistance. All structural components utilize high-strength hot-dip galvanized steel sheets with exceptional corrosion resistance, ensuring a building lifespan exceeding 70 years.Energy Efficiency & Environmental SustainabilityLight steel structures are 100% recyclable. Optimized wall and roof systems deliver superior thermal insulation, soundproofing, and waterproofing, reducing energy consumption by 65% compared to traditional brick-concrete structures.High Prefabrication, Labor SavingsAll building materials for light steel integrated houses can be factory-produced and prefabricated in batches with high mechanization. On-site construction eliminates wet processes, truly realizing residential industrialization.High Quality, High ComfortThe use of superior thermal insulation, soundproofing, and energy-efficient structures and materials significantly enhances indoor living comfort. Built-in piping and thinner walls effectively increase usable floor space (by 10–15% or more compared to conventional brick-and-concrete structures).Mature Technology and Comprehensive SupportThrough advanced technology adoption and years of practical experience, our company has established a complete, mature system covering technology, construction, quality management, and after-sales service. This has fostered a stable, comprehensive supply chain for supporting materials.Construction Process

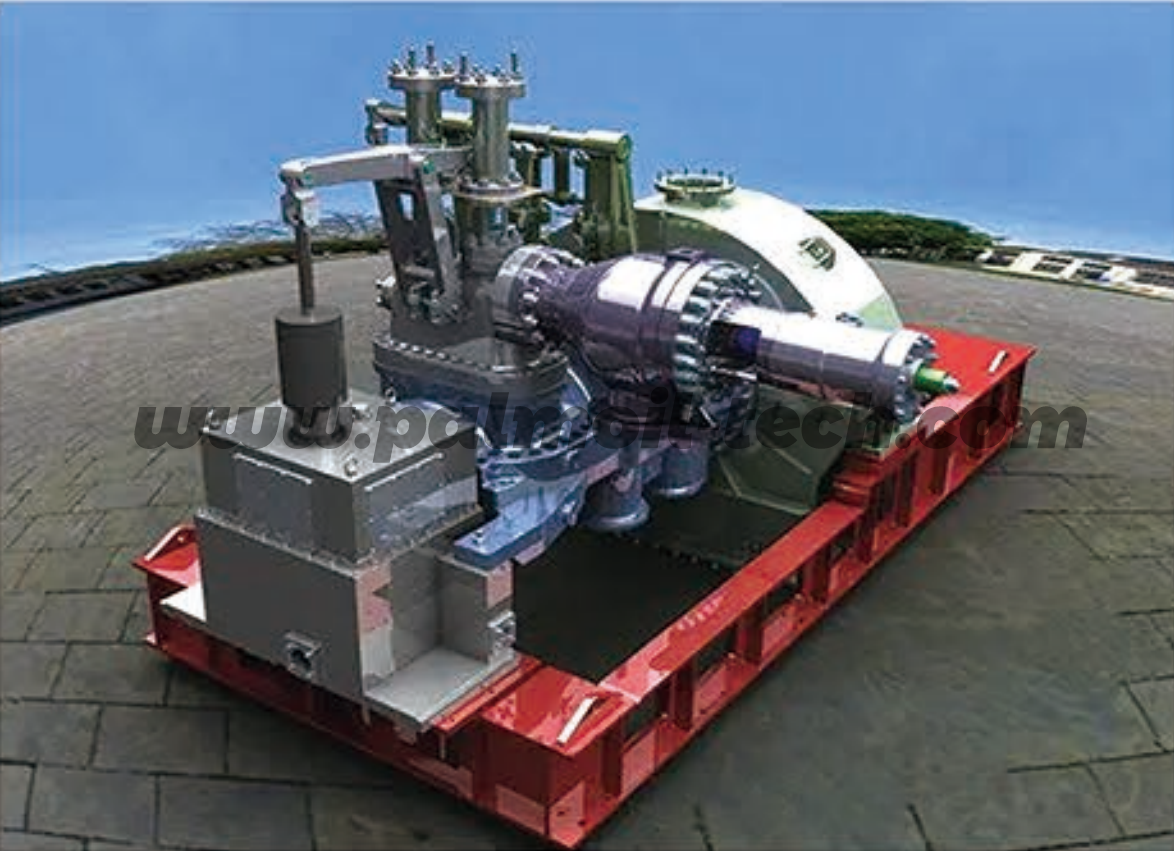

Extraction condensing steam turbine are single-cylinder, single-shaft impulse types with a single-stage regulating extraction. The unit's industrial extraction volume and electrical load can be automatically adjusted according to user requirements, and pure condensing operation is also permitted. All units in this series consist of rotor and stator components. The rotor adopts a sleeve-type structure, while the stator includes the cylinder, nozzles and baffles, labyrinth steam seals, bearings, and other parts. The high-medium cylinder lift plate-type regulating steam valve is mechanically linked to the hydraulic motor of the speed control system via levers. This series supports fully hydraulic speed control systems, imported governors, electro-hydraulic converters, automatic high-speed extraction devices, and various safety components and monitoring instruments. Single-extraction steam turbine. Composed of high-pressure and low-pressure sections, it functions as a combination of a back-pressure turbine and an extraction turbine. Fresh steam enters the high-pressure section to perform work. After expanding to a certain pressure, it splits into two streams: one is extracted to supply heat users, while the other enters the low-pressure section for further expansion and work before being discharged into the condenser.Steam Turbine Structural Features:. Configuration: Quick-assembly multi-stage steam turbine· Arrangement: Double-deck· Mechanical Speed Control: Fully hydraulic regulation· Electronic Speed Control: Electro-hydraulic converter governor, integrated control system comprising four major systems (governor, control, detection, protection)· Overspeed Protection: Mechanical fly-hammer protection with electromagnetic valve electronic intelligent control· Steam Seal Type: Stainless steel labyrinth steam seal, honeycomb contact steam seal· Main Steam Valve: Integrated automatic main steam valve (combination valve with quick-closing regulation)· Main shaft assembly: Restart stage rotor blades, interference fit between rotor and rotor blades· Lubrication system: Oil lubrication (with integrated lubrication station)· Thermal expansion compensation: Sliding thermal compensation for front bearing support· Electrical configuration: Complete set of electrical control cabinets, protection cabinets, main control cabinets, with domestic generator (voltage 400-6300-10050V)· Turbine Turning Method: Manual or ElectricThe design extraction pressure is determined based on thermal user requirements and controlled by a pressure regulator to maintain stable extraction pressure. The power output of a single extraction steam turbine is the sum of power generated by the high- and low-pressure sections, determined by the steam inlet volume and the steam flow through the low-pressure section. Adjusting the steam inlet volume allows for different power outputs. Therefore, within a certain range, both thermal and electrical load requirements can be simultaneously met. When the heat extraction steam flow is zero, a single extraction steam turbine functions as an extraction condensing turbine. If all steam entering the high-pressure cylinder is extracted for heat users, it operates as a back-pressure turbine. However, in actual operation, a certain amount of steam must flow through the low-pressure section into the condenser to cool the low-pressure cylinder and dissipate heat generated by friction losses. The minimum required flow rate is approximately 10% of the low-pressure cylinder's design flow rate.

A supplementary steam turbine refers to a turbine where, in addition to the main steam entering through the main steam valve and regulating valve to drive the turbine blades, one or more streams of low-pressure steam also enter the turbine through the rear stages to drive the turbine blades.Reheat steam turbines are widely used in self-owned power plants or small-to-medium-sized power plants within industries such as cement, chemical, petroleum, metallurgy, coking, biomass energy, and waste incineration. They effectively utilize low-parameter energy sources like waste steam generated during production processes.Turbine Structural Features:· Structural Type: Quick-assembly multi-stage steam turbine· Arrangement: Double-deck· Mechanical Speed Control: Fully hydraulic regulation· Electronic speed regulation (domestic or imported): Electro-hydraulic converter governor, integrated control system governor with four major functions (speed regulation, control, detection, protection)· Overspeed protection: Mechanical flyweight protection and electromagnetic valve electronic intelligent control· Steam seal type: Stainless steel labyrinth steam seal, honeycomb contact steam seal· Main steam valve: Integrated automatic main steam valve (combination valve with quick-closing regulation)·Main shaft assembly: Multi-speed impeller blades, interference fit between rotor and impeller·Lubrication system: Oil lubrication (with integrated lubrication station)·Thermal expansion compensation: Sliding thermal compensation for front bearing support·Electrical configuration: Complete set of electrical control cabinets, protection cabinets, main control cabinets, with domestic generator (voltage 400-6300-10050V)· Turntable Method: Manual or Electric

Condensing steam turbines refer to turbines where steam, after expanding and performing work within the turbine, enters the condenser to condense into water, with only a small portion escaping through shaft seals. The condensing equipment primarily consists of the condenser, circulating water pump, condensate pump, and ejector. Exhaust steam from the turbine enters the condenser, where it is cooled by circulating water and condensed into liquid water. This condensate is pumped out by the condensate pump, heated through multiple stages of heaters, and then fed back to the boiler as feedwater. During condensation within the condenser, the steam's volume rapidly contracts, creating a vacuum in the previously steam-filled enclosed space. This reduces the turbine's exhaust pressure, increasing the ideal enthalpy drop of the steam and thereby enhancing the plant's thermal efficiency. Non-condensable gases (primarily air) in the exhaust steam are extracted by the ejector to maintain the required vacuum level.Performance Characteristics:Condensing steam turbine units are multi-stage condensing turbines featuring high steam cycle utilization. They can extract steam for industrial processes or heating systems. The turbine exhaust enters the condenser, where it condenses into water, is recovered, reheated, and returned to the boiler for reuse. The turbine exhaust pressure is below atmospheric pressure. Operating safely and reliably, it is widely applied across multiple industries including thermal power generation, petroleum, chemical processing, printing and dyeing, textiles, cement, sugar refining, and papermaking.Structure: Quick-assembly double-support impulse multi-stage small steam turbineLayout: Single-deck or double-deckSpeed Control System: American Company 505 digital governor, German electro-hydraulic converter, hydraulic actuator manufactured with Siemens technologyOverspeed Protection: Dual mechanical fly-hammer type with electromagnetic valve and electronic intelligent controlSteam Seal Type: Stainless steel labyrinth steam sealMain Steam Valve: Integrated automatic main steam valve (combination regulating valve)Main shaft assembly: Redundant-speed stage rotor blades, interference fit between rotor and rotor blades, blades in embedded configurationLubrication system: Forced oil lubrication with oil tank, thin oil station, and coolerThermal expansion compensation: Sliding thermal compensation for front bearing supportElectrical configuration: Complete set of electrical control cabinets, protection cabinets, main control cabinets, paired with Siemens generatorCranking device: Electric cranking

We are industry leaders in micro-turbine manufacturing, boasting extensive experience, low profit margins, and high quality. Our operations rely on consistent production volumes to sustain the company. We welcome more clients to partner with us, driving us to produce even more efficient turbines.Performance Features:The M and H series turbines include back-pressure and condensing types. Impeller pitch circle diameters range from 380 to 500 mm, with main shaft speeds of 3000 and 5600 rpm. They utilize fresh steam or waste heat exhaust steam, saturated or superheated steam, with inlet steam pressure as low as 0.15 MPa. Power range: 1KW-650KW power generation turbine units. Primarily applied in ceramics, cement, power plants, chemical, chemical fiber, papermaking, sugar refining, steel, waste treatment, and energy utilization sectors such as corporate captive power stations, district cogeneration, municipal waste-to-energy plants, and gas-steam combined cycle power generation. The equipment offers lower operating costs and more significant economic benefits. Our company is committed to providing users with first-class products and premium services!Unit Features:Wide operating range: 0.15 MPa to 2.5 MPa working pressure.Single-layer skid-mounted installation design tailored to power requirements and user specifications.Also known as micro-turbines, these units feature simple installation—fully assembled within 5 days of delivery and commissioned within 2 days.Control Method:Simple structure, easy operation, high safety factor, equipped with a human-machine interface touchscreen control panel.Steam source can be either superheated steam or saturated steam.The turbine generator set adopts a direct-coupling configuration, ensuring high safety, long service life, and reduced susceptibility to damage.Key Point:Custom-designed turbines tailored to actual user parameters to accommodate diverse steam sources.