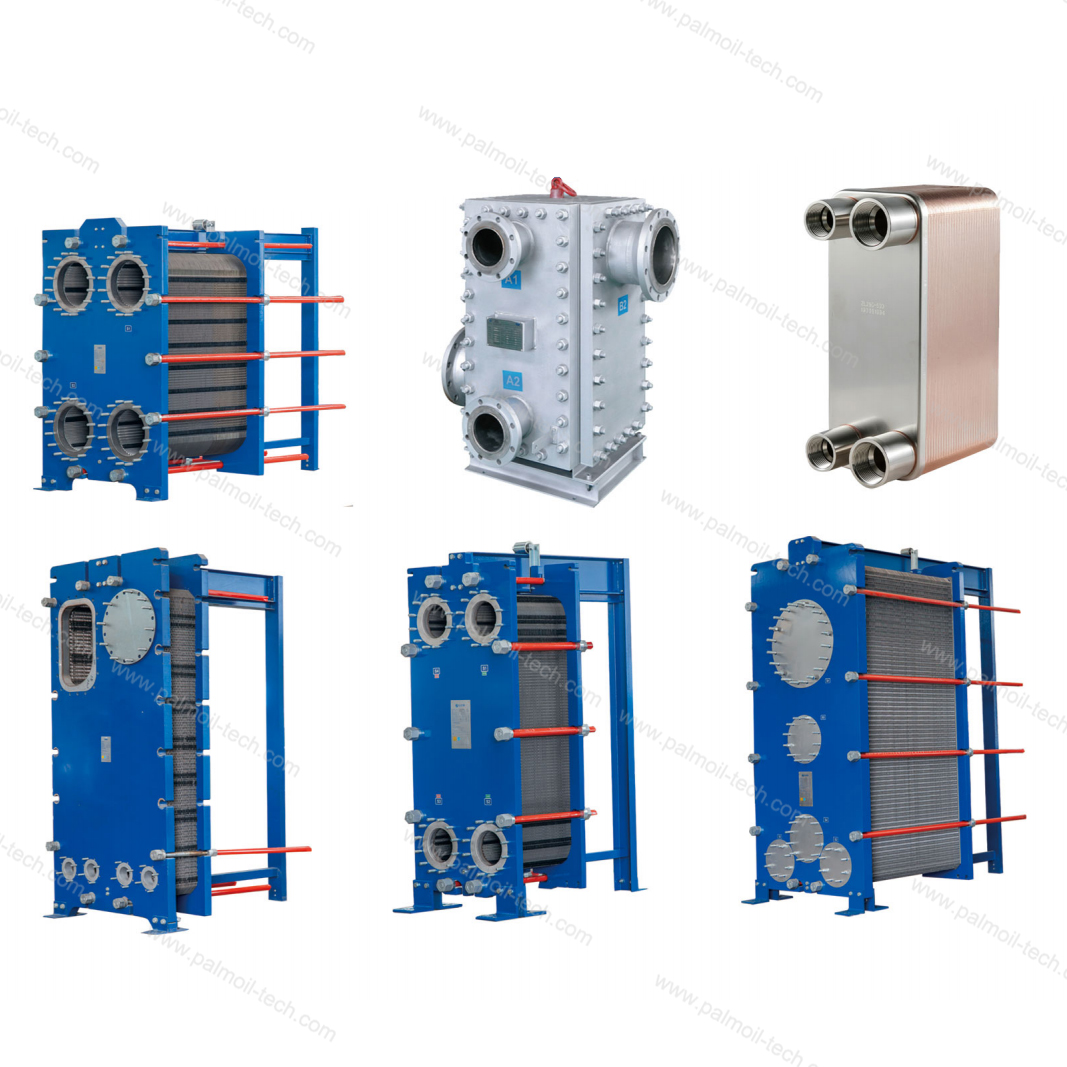

Plate heat ex-changer is made of many corrugated sheets at a certain interval, sealed by gaskets on all sides, and the plates and gaskets of the heat ex-changer are pressed and overlapped by a frame. The four corner holes of the plates and gaskets form the distribution pipes and collection pipes of the fluid, and at the same time, the cold and hot fluids are reasonably separated, so that they flow in the flow channels on both sides of each plate, and heat exchange is carried out through the plates.Main categories:1. Removable plate heat ex-changer (TGS, LTG series)2. Standard brazed plate heat ex-changer (TGL series)3. Removable fully welded plate heat ex-changer (QY series)4. Circular shell and tube heat ex-changer (QYS series)5. Bacchus plate Evaporator, Condenser (TGE, TGE series)Advantages and disadvantages of plate heat ex-changer:1. Compact structure, large heat exchange area per unit volume.2. Strong adaptability, the required heat exchange area can be met by adding or reducing plates.3. Small heat loss.4. Due to the small plate gap (2-8mm), the material can pass through quickly and thinly, and the heat exchange temperature can be accurately controlled.Disadvantages:1. Due to the limitation of the structural form, a rubber sealing gasket must be used, and the sealing perimeter is long and difficult to seal.2. The pressure bearing capacity is low (not higher than 2Mpa), and the operating temperature (not higher than 180℃) is limited by the temperature re

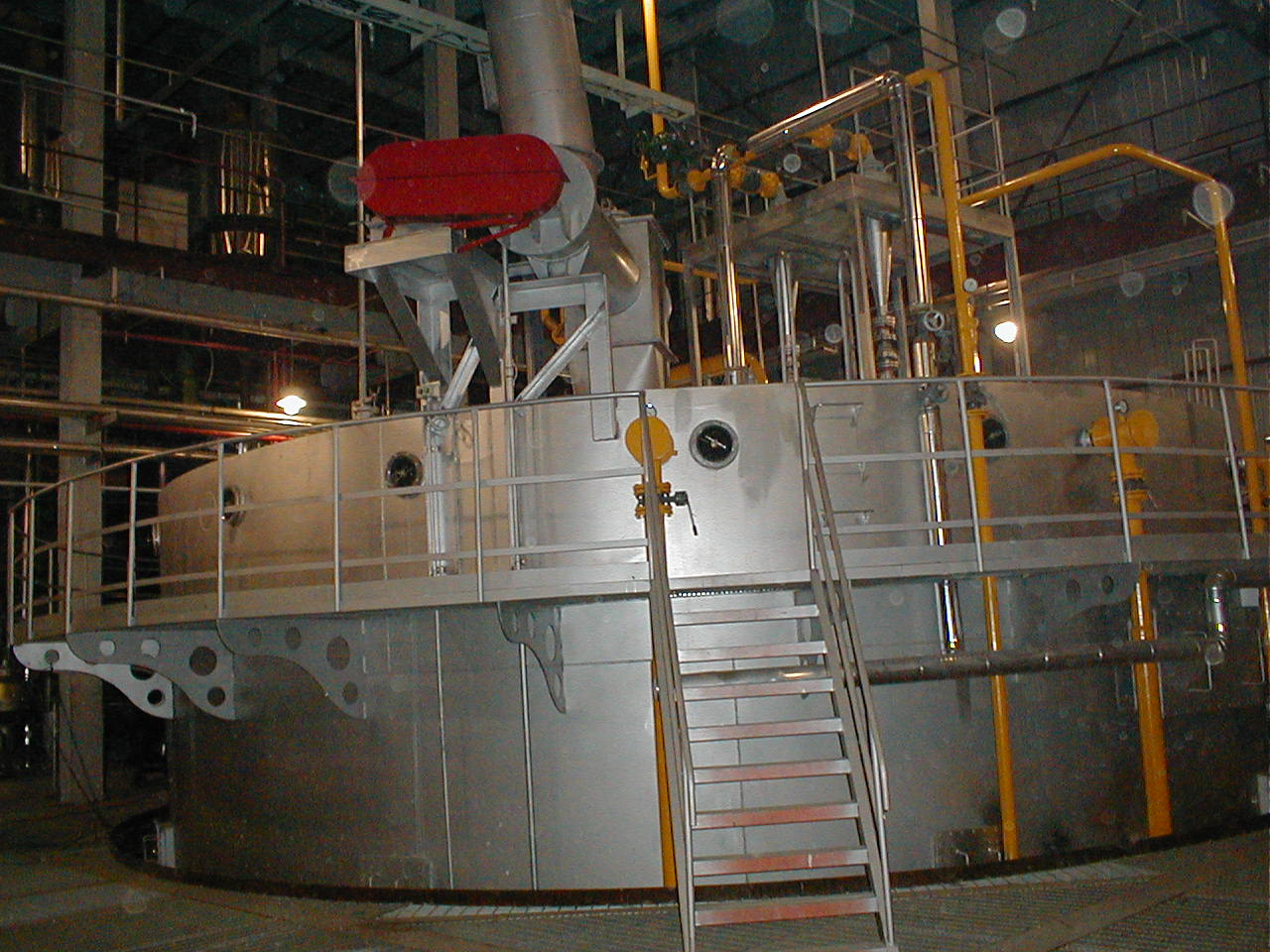

I. OverviewAnnular Leachers are efficient solid-liquid extraction equipment widely used for vegetable oilseed leaching.II. Working PrincipleMaterial Handling & Spraying: Material is fed by scraper conveyor and sprayed counter-currently with miscella from concentrated to dilute.Leaching & Draining: Fresh solvent is sprayed last. Drained wet meal is discharged to desolventizer; miscella goes to evaporation.Solvent Recovery: Filtered miscella is pumped to a holding tank; dilute miscella recirculates.III. Technical FeaturesAnnular Design: Material turnover ensures thorough leaching and low residual oil.Shallow Material Bed & V-Shaped Grids: Dead-zone-free movement and self-cleaning grids ensure efficient drainage, reducing solvent in wet meal.Unique Sealing: Prevents solvent leakage from main shaft, enhancing safety.Uniform Feeding/Discharge: Ensures stable system pressure.IV. ApplicationsSuitable for leaching rice bran (high powder content), soybeans, rapeseed, etc.V. Equipment SelectionCapacity: 50-5000 TPDSolvent Consumption: ≤0.6 kg/ton material, Recovery >99.5%Steam Consumption: ≤280 kg/ton material (0.8MPa)VI. AdvantagesHigh leaching efficiency, especially for powdered materials (e.g., rice bran, palm meal)Energy-saving (low solvent/steam consumption)Stable operation with low maintenanceSafe and reliable (no solvent leakage)Annular Leachers are efficient, energy-saving, and safe, making them mainstream in oil processing.

I. Working PrincipleThe Vertical Leacher is equipment used in the oil processing industry to extract oil from oilseeds. It utilizes a vertical leaching vessel where oilseeds contact solvents (e.g., hexane). The solvent dissolves the oil, forming miscella. The miscella undergoes evaporation and stripping to separate the solvent, yielding pure oil. Its vertical design enablesperiodic batch processing in single vessels, facilitating production coordination and suiting intermittent operations.II. Technical FeaturesVertical Structure: Space-efficient design enhances productivity.High-Pressure Operation: Improves leaching efficiency in specific applications.Mechanical Agitation-Free: First-generation models eliminate complex stirring mechanisms, reducing maintenance.Multi-Stage Series Operation: Enhances extraction efficiency through cascading vessels.Efficient Solvent Recovery: Integrated systems separate and recycle solvents from miscella.III. ApplicationsOil Processing: Extracts oil from palm kernel meal, soybeans, rapeseed, peanuts, etc.Metallurgy: Used in high-pressure acid leaching (HPAL) of laterite nickel ore to extract nickel and cobalt.Sugar Industry: Extracts sucrose from sugar beet cells.IV. Equipment SelectionCapacity: Match processing capability to production scale.Solvent Consumption: Prioritize low-solvent models to reduce costs.Steam Consumption: Select energy-efficient designs.Material: Opt for corrosion-resistant materials (e.g., titanium-clad steel) for longevity.V. AdvantagesHigh Efficiency: Vertical design and pressure operation optimize extraction.Energy Savings: Efficient solvent recovery and low steam consumption lower operating costs.Operational Stability: Agitation-free design minimizes complexity and maintenance.Safety & Reliability: Stable operation reduces safety risks.Vertical Leachers are efficient, energy-saving, and safe, making them essential in oil processing and ore leaching industries.

I. Working PrincipleMaterial Handling & Spraying: Prepared flakes or expanded meal enters drag chain frames, forming a material bed. Solvent is sprayed, establishing a liquid level on the bed.Leaching & Draining: Chains driven by a transmission slowly push material through isolated frames. This minimizes miscella mixing between stages, maintaining a steep concentration gradient for enhanced mass transfer. Material is dragged over upper/lower grid plates, improving utilization. A mid-process flip enhances leaching uniformity.Miscella Circulation: Repeated solvent/miscella spraying dissolves oil, forming miscella. Filtered miscella flows to collection hoppers. Concentrated miscella is pumped to holding tanks for evaporation/stripping; dilute miscella recirculates.Wet Meal Handling: After ~60 mins leaching, spent meal is pushed to the discharge by scrapers and conveyed to the desolventizer.II. Technical FeaturesExcellent Sealing: Fully enclosed design minimizes solvent loss.Frequency-Controlled Speed: Adjustable chain speed via frequency converter optimizes solvent penetration for different materials.Independent Leaching Cells (Drag Frames): Prevents miscella cross-flow between stages, maintaining concentration gradients.Full Counter-Current Flow: Maximizes miscella concentration and leaching efficiency.Auto-Speed Adjustment: Reduces failure rates and ensures stable operation.III. Key ComponentsMain drive unitTensioning deviceDriven unitFeed hopperDrag chain with scrapersGrid plate/screen frameFeed rate controllerSpraying systemSight glass flushing deviceEnclosed casingDrive systemUpper/lower miscella hoppersIV. AdvantagesHigh Efficiency: Low bed height improves solvent penetration; material flipping loosens/realigns the bed.Energy Savings: Optimized spraying/draining reduces solvent & energy use.Stable Operation: Robust design ensures low failure rates.Safety & Reliability: Sealed enclosure minimizes leakage risks.This efficient, energy-saving, and reliable leacher is a mainstream choice in oil processing.