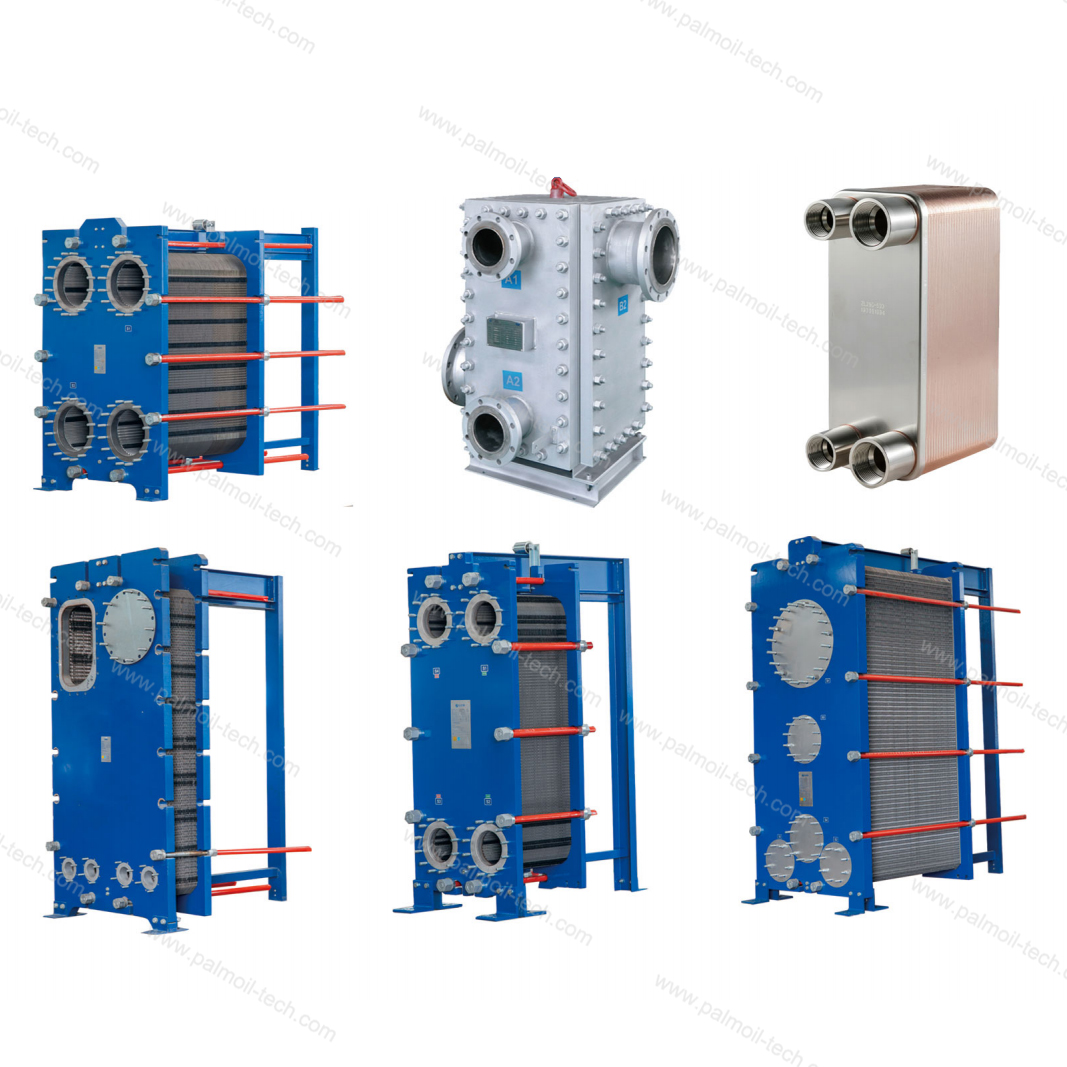

Plate heat ex-changer is made of many corrugated sheets at a certain interval, sealed by gaskets on all sides, and the plates and gaskets of the heat ex-changer are pressed and overlapped by a frame. The four corner holes of the plates and gaskets form the distribution pipes and collection pipes of the fluid, and at the same time, the cold and hot fluids are reasonably separated, so that they flow in the flow channels on both sides of each plate, and heat exchange is carried out through the plates.Main categories:1. Removable plate heat ex-changer (TGS, LTG series)2. Standard brazed plate heat ex-changer (TGL series)3. Removable fully welded plate heat ex-changer (QY series)4. Circular shell and tube heat ex-changer (QYS series)5. Bacchus plate Evaporator, Condenser (TGE, TGE series)Advantages and disadvantages of plate heat ex-changer:1. Compact structure, large heat exchange area per unit volume.2. Strong adaptability, the required heat exchange area can be met by adding or reducing plates.3. Small heat loss.4. Due to the small plate gap (2-8mm), the material can pass through quickly and thinly, and the heat exchange temperature can be accurately controlled.Disadvantages:1. Due to the limitation of the structural form, a rubber sealing gasket must be used, and the sealing perimeter is long and difficult to seal.2. The pressure bearing capacity is low (not higher than 2Mpa), and the operating temperature (not higher than 180℃) is limited by the temperature re

Function: Removes color, impurities, and odors from solutions via adsorption, chemical reaction, or physical separation.I. ApplicationsFood Industry: Sugar, MSG, glucose, starch syrup refiningPharmaceuticals: Intermediate purification, pyrogen removalChemicals: Dye intermediates, additives processingEdible Oils: Pigment removal during refiningII. Working PrinciplesMethodMechanismAdsorptionActivated carbon/clay traps pigments in microporesChemical ReactionDecolorizers (e.g., oxidants) break chromophores in high-COD wastewaterPhysical SeparationFiltration/centrifugation removes particulate impuritiesIII. Structural FeaturesVertical Enclosed Design: Prevents dust contamination.Custom Agitators: Low-noise, material-specific mixing (e.g., shear-sensitive biologics).Jacketed Heating: Steam/hot water circulation for optimal adsorption temperature (60–110°C).Insulation Layer: Cross-linked PE foam minimizes heat loss (<5% energy dissipation).Sanitary Construction:Mirror-polished interior (Ra ≤0.6 µm)Smooth radius transitions at all ports/sight glassesCIP-compatible, dead-leg-free designIV. AdvantagesAspectBenefitEfficiencyReduces color intensity by 90–99% (Lovibond scale)MultifunctionalityIntegrates decolorization, filtration, dryingEnergy ConservationOptimized heating/agitation cuts power by 15–30%Eco-FriendlinessMinimizes chemical consumption; recyclable adsorbentsReliabilityFDA-compliant materials (SS316L/304); >20,000-hour MTBFV. Application ExamplesEdible Oil Bleaching:Reduces carotenoids/chlorophyll in palm/soybean oilResidual pigments: ≤0.1 RBU (Rosenthal scale)Textile Effluent Treatment:Cuts COD by 40–70%; achieves discharge standards (<50 Pt-Co units)Technical Specifications(Standard Model):Capacity: 0.5–50 m³Working Pressure: -0.1 to 0.5 MPaAdsorbent Dosage: 0.2–5% (w/v)Typical Cycle Time: 30–120 minCritical for meeting ISO 22000, GMP, and REACH compliance in sensitive industries.

Crystallization TankFunction: Separates high-melting stearin from low-melting olein in palm oil via controlled cooling crystallization, enhancing purity and tailoring melting points for specific applications.II. Working PrincipleCrystal Melting:Heats refined palm oil to70°Cto dissolve existing crystals.Crystallization & Growth:Cools oil gradually viachilling coils(using cooling tower/chiller systems).Agitation ensures uniform crystal formation of stearin (high-melting fraction).Separation:Filters crystals using membrane filters;Olein(liquid) → Storage tanksStearin(solid) → Recovery vesselsIII. Technical FeaturesFeatureBenefitHigh-Efficiency CrystallizationChilling coils + agitation enable uniform cooling and crystal growth.Precision ControlAutomated temperature regulation (±0.5°C) optimizes crystal size/distribution.Energy-Saving DesignRecirculated cooling water/chilled brine reduces energy use by 20–30%.Integrated FunctionCompatible with filtration systems for continuous separation.IV. ApplicationsPalm Oil Fractionation:Olein: Used in frying oils, margarine.Stearin: Raw material for candles, soaps, and cocoa butter substitutes.Palm Oil Dewaxing:Removes wax crystals to improve clarity and cold stability.V. Key AdvantagesIncreases olein yield by≥15%vs. conventional methodsAchievesIV 56–59 (olein)andIV 32–35 (stearin)Reduces filtration cycle time by40%Meets ISO 22000 & HACCP standardsTechnical Specifications(Standard Unit):Capacity: 5–200 tons/batchCooling Rate: 0.1–0.5°C/minOperating Pressure: -0.05 to 0.3 MPaPower Consumption: 0.8–1.2 kW/tonEssential for producing specialty fats with customized melting profiles (MP 24°C olein; MP 50°C stearin).