I. Working PrincipleThe Vertical Leacher is equipment used in the oil processing industry to extract oil from oilseeds. It utilizes a vertical leaching vessel where oilseeds contact solvents (e.g., hexane). The solvent dissolves the oil, forming miscella. The miscella undergoes evaporation and stripping to separate the solvent, yielding pure oil. Its vertical design enablesperiodic batch processing in single vessels, facilitating production coordination and suiting intermittent operations.II. Technical FeaturesVertical Structure: Space-efficient design enhances productivity.High-Pressure Operation: Improves leaching efficiency in specific applications.Mechanical Agitation-Free: First-generation models eliminate complex stirring mechanisms, reducing maintenance.Multi-Stage Series Operation: Enhances extraction efficiency through cascading vessels.Efficient Solvent Recovery: Integrated systems separate and recycle solvents from miscella.III. ApplicationsOil Processing: Extracts oil from palm kernel meal, soybeans, rapeseed, peanuts, etc.Metallurgy: Used in high-pressure acid leaching (HPAL) of laterite nickel ore to extract nickel and cobalt.Sugar Industry: Extracts sucrose from sugar beet cells.IV. Equipment SelectionCapacity: Match processing capability to production scale.Solvent Consumption: Prioritize low-solvent models to reduce costs.Steam Consumption: Select energy-efficient designs.Material: Opt for corrosion-resistant materials (e.g., titanium-clad steel) for longevity.V. AdvantagesHigh Efficiency: Vertical design and pressure operation optimize extraction.Energy Savings: Efficient solvent recovery and low steam consumption lower operating costs.Operational Stability: Agitation-free design minimizes complexity and maintenance.Safety & Reliability: Stable operation reduces safety risks.Vertical Leachers are efficient, energy-saving, and safe, making them essential in oil processing and ore leaching industries.

I. Working PrincipleMaterial Handling & Spraying: Prepared flakes or expanded meal enters drag chain frames, forming a material bed. Solvent is sprayed, establishing a liquid level on the bed.Leaching & Draining: Chains driven by a transmission slowly push material through isolated frames. This minimizes miscella mixing between stages, maintaining a steep concentration gradient for enhanced mass transfer. Material is dragged over upper/lower grid plates, improving utilization. A mid-process flip enhances leaching uniformity.Miscella Circulation: Repeated solvent/miscella spraying dissolves oil, forming miscella. Filtered miscella flows to collection hoppers. Concentrated miscella is pumped to holding tanks for evaporation/stripping; dilute miscella recirculates.Wet Meal Handling: After ~60 mins leaching, spent meal is pushed to the discharge by scrapers and conveyed to the desolventizer.II. Technical FeaturesExcellent Sealing: Fully enclosed design minimizes solvent loss.Frequency-Controlled Speed: Adjustable chain speed via frequency converter optimizes solvent penetration for different materials.Independent Leaching Cells (Drag Frames): Prevents miscella cross-flow between stages, maintaining concentration gradients.Full Counter-Current Flow: Maximizes miscella concentration and leaching efficiency.Auto-Speed Adjustment: Reduces failure rates and ensures stable operation.III. Key ComponentsMain drive unitTensioning deviceDriven unitFeed hopperDrag chain with scrapersGrid plate/screen frameFeed rate controllerSpraying systemSight glass flushing deviceEnclosed casingDrive systemUpper/lower miscella hoppersIV. AdvantagesHigh Efficiency: Low bed height improves solvent penetration; material flipping loosens/realigns the bed.Energy Savings: Optimized spraying/draining reduces solvent & energy use.Stable Operation: Robust design ensures low failure rates.Safety & Reliability: Sealed enclosure minimizes leakage risks.This efficient, energy-saving, and reliable leacher is a mainstream choice in oil processing.

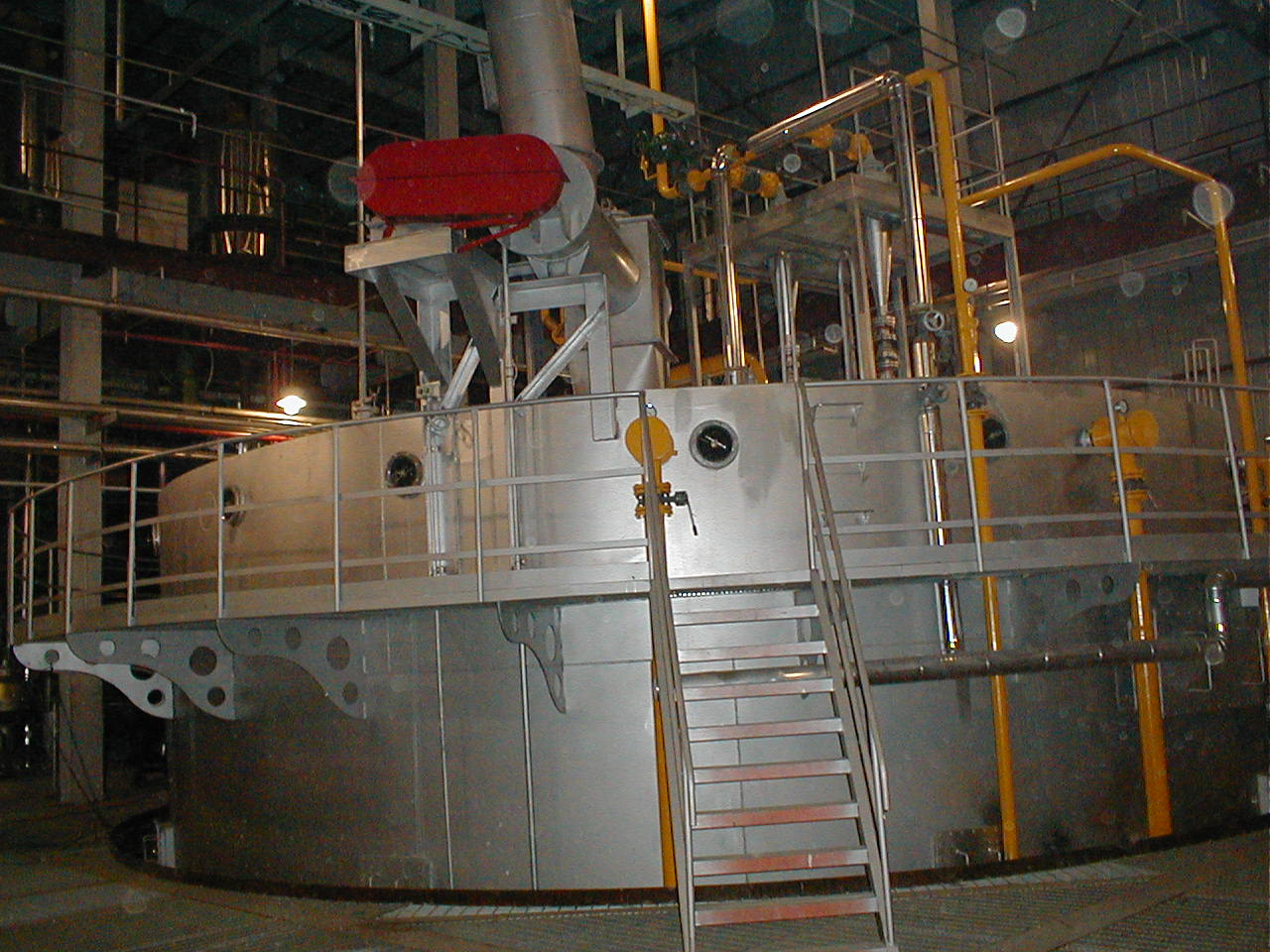

I. Function & PurposeThe DTDC is essential in oil extraction plants fordesolventizing wet mealandinactivating anti-nutritional factors. It integrates desolventizing, toasting, drying, and cooling into one unit, ensuring simple operation and stable product quality. It processes solvent-laden wet meal from leachers.II. Working PrinciplePre-desolventizing Layer: Indirect steam heats wet meal, evaporating partial solvent.Desolventizing-Toasting Layer: Direct steam accelerates solvent evaporation. Agitation and negative pressure enhance desolventizing.Drying Layer: Hot air reduces moisture content.Cooling Layer: Cools meal to near ambient temperature for storage/transport.III. Technical FeaturesSteam-Permeable Trays: Ensure even gas penetration without meal leakage, reducing direct steam usage.Automatic Discharge Valves: Maintain constant bed depth and adequate retention time.Roller-Bearing Sealed Gates: Ensure flexible, long-lasting operation and prevent solvent leaks.Wet Scrubber: Atomizing nozzles capture fine meal particles from exhaust gases.Offset Curved Agitators: Provide thorough meal mixing.IV. AdvantagesInactivates Anti-Nutrients: Destroys urease, trypsin inhibitors, etc., improving meal nutritional value.Controls Protein Denaturation: Enhances meal NSI (Nitrogen Solubility Index).Adjusts Color, Flavor & Particle Size.Minimizes Residual Solvent & Moisture: Ensures safe meal handling with low solvent consumption.V. Specifications & Technical ParametersModelCapacity (t/d)Power (kW)YФ 2500×730030YФ 3200×760055YФ 3600×7100090YФ 4000×91500132YФ 5000×92000220YФ 5000×113000250YФ 5600×114000315YФ 5600×135000250+90YФ 6200×146000280+110VI. SummaryThe DTDC excels as the optimal wet meal desolventizer in oil extraction plants. Its integrated design efficiently performs desolventizing, toasting, drying, and cooling. Unique features ensurelow solvent consumption,high meal quality, andenergy efficiency.

Core Function: Separates solvent from oil-solvent mixture (miscella) to produce concentrated crude oil.I. Working PrinciplePre-treatment: Miscella from leacher is filtered/centrifuged to remove solids.Multi-Stage Evaporation:1st Stage: Long-tube (rising-film) evaporator at 60–70°C → Concentrates miscella to ~60% oil.2nd Stage: 90–120°C → Concentrates to 90–95% oil.Steam Stripping: Residual solvent removed via direct/indirect steam in stripping column under vacuum.II. Technical FeaturesHigh-Efficiency Evaporation: Thin-film design in long-tube evaporators enhances heat transfer.Vacuum Operation: Lowers solvent boiling point, reducing energy consumption.Solvent Recovery: Vapors condensed and recycled.Progressive Concentration: Two-stage evaporation minimizes thermal damage.III. ApplicationsUsed in oil processing (soybean, rapeseed, sunflower) and solvent-liquid separation industries.IV. AdvantagesHigh Oil Purity: ≤0.1% residual solvent.Energy-Efficient: Vacuum + staged evaporation cuts steam use by 25–30%.Eco-Friendly: >99% solvent recovery rate.Low Maintenance: Robust design ensures continuous operation.

Function: Removes gum impurities (phospholipids, proteins, mucilaginous substances) from crude oil to improve quality, storage stability, and downstream processing efficiency.I. Working PrincipleBased onhydrophilicityof gums:Hydration Degumming:Hot water/electrolyte (NaCl, phosphoric acid) is added to heated oil (60–85°C) under agitation.Hydratable phospholipids swell, coalesce, and settle as sludge.Acid Degumming:Inorganic/organic acids (phosphoric/citric acid) remove both hydratable andnon-hydratable phospholipids.Ideal for high-purity oils (e.g., physical refining).II. Technical FeaturesHigh-Efficiency Separation: Optimized control of temperature, agitation (30–60 rpm), and water dosage (1–3%).Multifunctional Design: Integrates degumming & deacidification in one vessel.Automated Control: Real-time monitoring of key parameters (viscosity, pH, temperature).III. ApplicationsEdible Oils: Soybean, rapeseed, sunflower oil refining.Industrial Oils: Removal of gums & impurities.IV. AdvantagesAspectBenefitOil QualityReduces phosphorus to ≤10 ppm; improves NSI & oxidative stability.Cost SavingLowers chemical/energy consumption in downstream neutralization.Eco-FriendlyMinimizes acid/water usage; sludge byproduct recyclable for lecithin.ReliabilityRobust construction (SS304/316L); CIP-enabled; maintenance-free seals.Key Specifications(Typical Industrial Unit):Capacity: 5–100 tons/batchOperating Temp: 60–90°CResidual Phosphorus:<10 ppmAcid Consumption: 0.05–0.2% (acid degumming)Agitation Power: 0.5–5 kWCritical for producing food-grade oils meeting Codex Alimentarius standards.

Product DescriptionThe Vibrating Cleaning Screen is a highly efficient and energy-saving screening equipment widely used in grain, oil, chemical, and food industries for raw material pretreatment. Utilizing high-frequency vibration, it separates impurities from raw materials based on differences in particle size, density, and shape, ensuring material purity and smooth downstream processing.Key FeaturesHigh-Efficiency Screening: High-frequency vibration enables rapid impurity separation with large processing capacity.Compact Structure: Space-saving design adapts to diverse production environments.User-Friendly Operation: Automated control system simplifies operation and maintenance.Durability: Constructed with wear/corrosion-resistant materials for extended service life.Adaptability: Adjustable vibration frequency/amplitude for various materials.Energy Efficiency: Low power consumption meets environmental standards.Working PrincipleComprising a vibrator motor, screen frame, mesh, and support structure, the equipment operates as follows:Material enters through the feed inletHigh-frequency vibration propels material across the screen surfaceParticles smaller than mesh openings pass through as productOversized impurities discharge separatelyApplicationsGrain Processing: Removes stones, mud, and metal from wheat, corn, riceOil Extraction: Pretreats oilseeds to improve extraction yieldChemical Industry: Purifies raw materials for quality controlFood Processing: Eliminates foreign matter to ensure safetyTechnical SpecificationsParameterValue/RangeScreening Accuracy0.5-10 mm (customizable)Capacity1-100 t/h (model-dependent)Vibration Frequency800-2000 rpm (adjustable)Motor Power1.5-7.5 kWScreen MaterialStainless steel/NylonMaintenance GuidelinesMonthly: Inspect screen mesh wear; replace damaged sectionsBi-weekly: Lubricate vibrator motor and bearingsShift-based: Clean residual material to prevent cloggingQuarterly: Verify electrical control system safetyConclusionWith its efficiency, durability, and energy-saving performance, the Vibrating Cleaning Screen is the optimal solution for raw material pretreatment across multiple industries. We deliver high-quality equipment to enhance productivity, reduce operational costs, and support sustainable production.